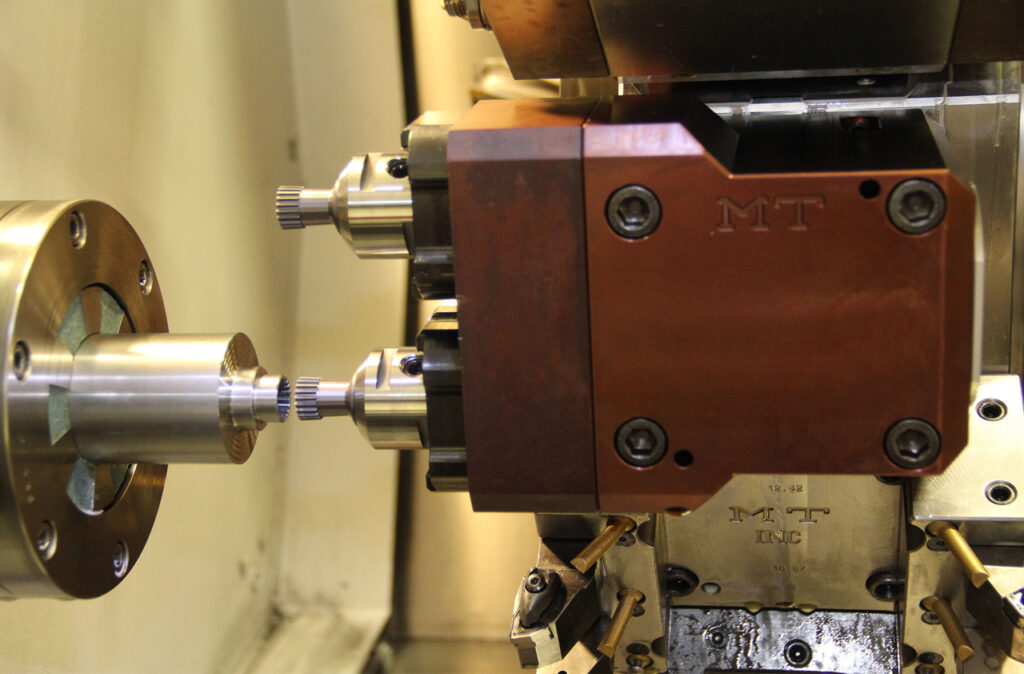

The new 91° multiple broaching driven toolholder designed by MT Marchetti allows the machining of internal and external profiles with different shapes (squares, hexagons, gears and special profiles) using shaped tools and with a great degree of accuracy and finishing. Small holes, from 2/3 mm up to 30 mm can be machined with a reduced tooling cost compared to other technologies like the gear hobbing or power skiving. The 91° multiple broaching driven toolholder works with an angle of 91° respect to the turret plane, allowing a synchronous machining with the rotation of the workpiece. The driven toolholder, combined with the polygon cutting function, ensures that both the workpiece and the shaped tool rotate at the same speed, guaranteing an excellent level of straightness accuracy even on long parts.

The multiple output allows, on machines with the Y axis, the roughing and finishing operations to be performed with one single driven toolholder, occupying a single station on the turret. Particular attention has been paid to the alignment of the outputs, which must be very careful not to compromise the quality of the machining.

For more information contact MT Marchetti.